Corning Switches from Copper Cables to Fiber Optic Cables in Data Centers

We have repeatedly heard about the need for fiber optic connections between data centers to support the growth of large-scale artificial intelligence (AI). However, there are still a large number of copper cables inside the data center, which provides a huge opportunity for optical suppliers such as Corning.

The need to change

Mike O’Day, Senior Vice President and General Manager of Corning’s Optical Communications Division, stated at the company’s investor event on Tuesday that the rise of AI has driven an increase in the number of graphics processing units (GPUs) in data center server racks, which means more fiber is needed to connect these GPUs.

O’Day also expressed similar views to Fierce in 2023, but due to the rise of generative AI and agent-based AI, this issue has become more urgent.

2025 will be the year of 72 GPU AI nodes (such as Nvidia’s Blackwell), “he said. These nodes will increase the fiber demand in the switch rack by four times, which brings huge opportunities for Corning

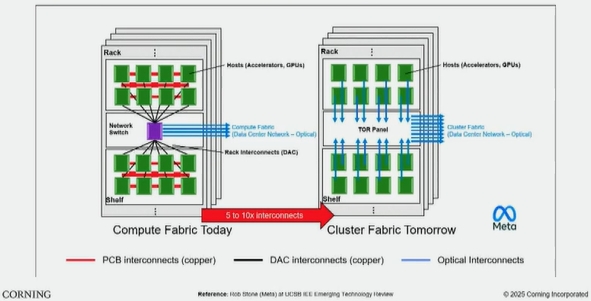

The key lies in the backend of the node, where there are bundles of copper cables. He explained that typically there are 2 miles of copper cables in each rack. In a typical 72 GPU node, there are six server racks, with fiber optic connections from the switch rack to each server rack, but “currently the optical signal terminates here”.

Benefits and challenges

Corning hopes to replace these copper cables with fiber optic technology. The potential revenue from doing so could be enormous: Dell’Oro Group predicts that by 2028, AI backend networks will grow at a compound annual growth rate (CAGR) of over 50%, reaching $20 billion.

However, this replacement may be a challenging task as copper cables are currently used in many areas of data centers, despite fiber optic being a more efficient connection method.

Copper cables are not only used in the internal wiring and power connectors of servers, as pointed out by mining company BHP, but also in the cooling systems and external cables that power data centers.

Bloomberg predicts that copper usage in North American data centers may increase by 1.1 million to 2.4 million tons by 2030. “With the increasing demand for AI, the power density and cooling requirements of server racks will also rise, which may further push up the intensity of copper usage, “Bloomberg said.

But Claudio Mazzali, Vice President of Global Research at Corning, believes that the shift from short-range copper interconnects to fiber optic in data center backend networks is “inevitable”.

He stated that we have witnessed a shift from electrical to optical applications, such as in underwater, long-distance, metropolitan, and access networks, to ‘compensate for signal loss on copper links’. Now, as mega scale enterprises double their efforts to build more capacity for AI, the architecture we see is “creating new demands, and copper electrical transmission will face challenges”.

As you know, electricity – not fiber optic – may be the biggest limiting factor for data center growth, especially as issues such as chip power levels and rack density become increasingly prominent.

Technical Details

“Mazzali pointed out that as data rates continue to increase, the number of GPUs per node will also increase. Imagine a node with hundreds of GPUs distributed across more than 10 racks. Once this happens, the interconnection between GPUs on the same node will need to be extended to over 30 meters, “he explained.

By then, “switching to fiber optic will be more cost-effective and energy-efficient,” Mazzali said.

He presented the current server rack architecture diagram of Meta and pointed out that “it is important to note that signals are only converted to optical signals at the network switches in the middle purple box.”

Although Mazzali cannot disclose how Corning will collaborate with partners to drive the future development of AI nodes, he points out that Co packaged optics technology will play a key role in addressing copper cable limitations in data centers.

Mazzali explained that although co packaging optical technology has been around for some time, it has attracted more attention as advanced chips generate 100Tbps of aggregated input/output.

“We started with hundreds of planes, each with a speed of over 100Gbps. Transmitting these signals through copper cables requires advanced digital signal processing or stronger forward error correction techniques, even if the distance is only a few centimeters, “he said.

IBM has actually developed a new co packaging optical technology that can solve this problem by allowing chips to communicate through optical fibers instead of electrical technology, thereby accelerating communication between chips.

Prospects of Generative AI

Overall, Corning is very optimistic about the value that generative AI can bring to its enterprise business. Corning CEO Wendell Weeks stated that the company achieved a “record breaking $2 billion” in corporate revenue in 2024, and “customer adoption rates continue to exceed our expectations

It is worth noting that Corning is helping Lumen meet the long-distance fiber optic transmission needs brought about by advances in AI. Last August, the two companies reached an agreement that Lumen would retain 10% of Corning’s global fiber optic capacity for the next two years.

“Our production has tripled every month this quarter, so this innovation is being translated into revenue streams and has a positive impact on our financial situation this year, “Weeks concluded.