Microsoft Collaborates with Corning to Expand Production of Hollow-core Fiber

To better support AI workloads, Microsoft is accelerating the global deployment of hollow-core fiber. This tech giant has reached an agreement with Corning and German supplier Heraeus to build a “cross-border production supply chain for large-scale production of next-generation fiber optics”. Microsoft announced this trend in its blog.

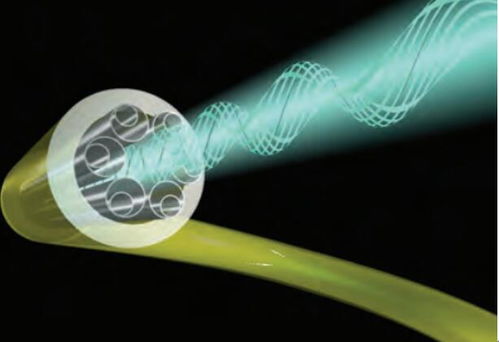

The difference between hollow-core fiber and traditional single-mode fiber is that it transmits optical signals through hollow channels filled with air instead of solid glass. Supporters of this technology believe that due to the faster propagation speed of light in air compared to glass, hollow-core fibers have the potential to provide higher bandwidth for delay sensitive applications.

For Corning, this is its first public announcement that it will manufacture hollow-core fibers. The company’s fiber optic products have attracted attention from companies such as Lumen, who has previously booked 10% of Corning’s global fiber optic capacity to build their enterprise fiber backbone network. Corning will produce hollow- core fiber at its North Carolina factory. Heraeus, a German company that provides quartz and fused silica products for the semiconductor, photonic and telecommunications industries, will manufacture the fiber in factories in Europe and the United States.

Current situation of deployment of hollow-core fiber

Microsoft has been laying out in the field of hollow-core fiber for some time now. The company began its deployment after acquiring Lumenisity, a supplier of hollow-core fiber, at the end of 2022. Lumensity has developed a method to reduce the data transmission loss of this technology. Microsoft also continues to invest in research and development, and recently announced with researchers from the University of Southampton in the UK the design of a kind of hollow-core fiber with a loss of less than 0.1 decibels per kilometer.

Researchers point out that the power drop of light only occurs after propagating about 33 kilometers in this new type of fiber optic cable, while standard telecommunications fibers (typically with signal loss of about 0.2 decibels per kilometer) can only transmit 15 kilometers and reach the same level of attenuation.

Although Microsoft is currently an important player in the field of hollow- core fiber, other companies are also exploring this technology. Operators such as British Telecom and Comcast have experimented with hollow-core fiber in their networks, with applications ranging from quantum key distribution to financial services. In China, optical communication supplier Changfei Fiber last year collaborated with China Mobile to launch what is claimed to be the world’s first 800G hollow fiber network.

Shortboard of hollow fiber optic cable

Despite ongoing testing and recent improvements in signal loss, the widespread adoption of hollow-core fibers may still take time. Derrick Lathrop, the project manager for Google’s long-distance network planning technology, commented on LinkedIn that fusing hollow core fibers requires “highly specialized equipment” that is not yet widely available. In addition, he stated that operators currently lack an external factory team specifically trained for hollow fiber, and the compressive and tensile resistance of hollow-core fiber is lower than that of single-mode fiber.

Lathrop added that the optical time domain reflectometer currently used for testing and maintaining fiber optic networks “cannot detect moisture, dust, or breakage inside hollow-core fibers – all of which can impair transmission performance”.