Microsoft Unveils “Black Tech”: Built-in Coolant in Chips

Microsoft President and CEO Satya Nadella announced on social media that the Microsoft team has achieved a significant breakthrough: a novel liquid cooling method utilizing microfluidic technology, which paves the way for more efficient, sustainable, and denser data centers than traditional approaches.

This is a liquid cooling technology that directly injects coolant into the chip, reportedly achieving 2-3 times better performance than traditional cold plate technology. If this technology becomes widely adopted in practical applications, it will not only represent a technical marvel but also likely bring about a comprehensive transformation across the entire chain—from chip design to data center layout.

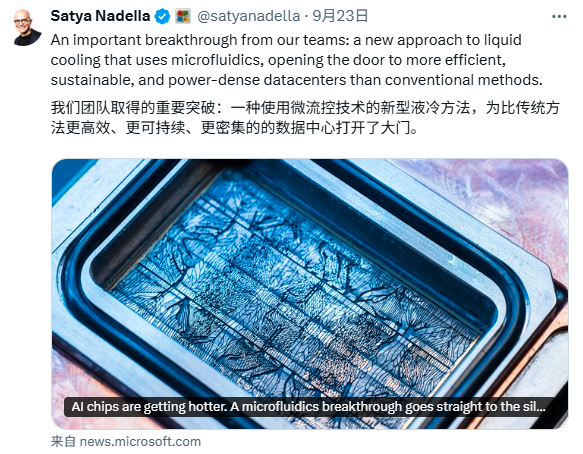

In-chip microfluidic

Microsoft refers to this technology as in-chip microfluidic, where micron-level channels are etched on the back of the chip, resembling a dense network of fine pipes like human hair. Specialized low-viscosity cooling fluid flows through these channels directly to the heat source of the chip, dissipating heat to cool the chip.

Sashi Majety, Senior Technical Program Manager at Microsoft’s Cloud Operations and Innovation Department, revealed that lab tests show microfluidic cooling achieves 2-3 times higher heat removal efficiency than cold plates, reducing peak temperature rise in GPU silicon cores by 65%. This means chips can operate stably at high frequencies without throttling due to overheating. More critically, there is potential for a 20%-30% improvement in power usage effectiveness (PUE), directly cutting data center operational costs.

Microsoft also provided a real-world test case for a Teams meeting server: Teams consists of approximately 300 microservices, with distinct peak and trough loads—such as the “hourly peak” during scheduled meetings. Microfluidics not only stabilizes peak heat but also supports “overclocking,” allowing brief performance boosts to handle high loads, significantly enhancing service stability and response speed. Jim Kleewein, a Microsoft Technical Fellow, emphasized: “Microfluidics comprehensively empowers the hardware foundation in terms of cost, reliability, speed, and sustainability.”

Risks and opportunities of liquid cooling for IDC operators

In recent years, the penetration of liquid cooling technology in data centers has significantly increased, particularly in AI and high-performance computing (HPC) scenarios, where it has become a standard feature in newly built data centers. It is projected that by 2028, the liquid cooling market in China will exceed 50 billion yuan.

The widespread adoption of liquid cooling has profoundly transformed the role of IDC service providers. In the past, IDCs centered around “rack space + power + network,” with a service model leaning toward standardized leasing. Today, the introduction of complex fluid systems in liquid cooling—especially as more chip-based servers come “pre-installed with liquid cooling”—is gradually shifting the responsibilities of IDC operators away from managing rack environments.

If Microsoft’s microfluidic technology achieves mass production, it will undoubtedly bring a “secondary impact” to the IDC industry. Unlike the “external contact” methods of cold plates and immersion cooling, microfluidics embeds the cooling fluid directly into the silicon layer of the chip, increasing thermal conduction efficiency by 2-3 times. However, the coupling of internal fluid exchange with the external environment may not be as tight as that of cold plates. Meanwhile, the high heat dissipation capability of chips will actually increase the overall cooling demand for data centers.

All of these will impact the operational model, even bringing IDC maintenance services back inside the cabinets. Additionally, microfluidic technology offers high heat dissipation efficiency, which also provides higher-quality waste heat, potentially leading to greater returns for IDC waste heat recovery systems.